LIT Electronic Technology Co., Ltd

LIT was founded in 2000, located in Dongguan City.

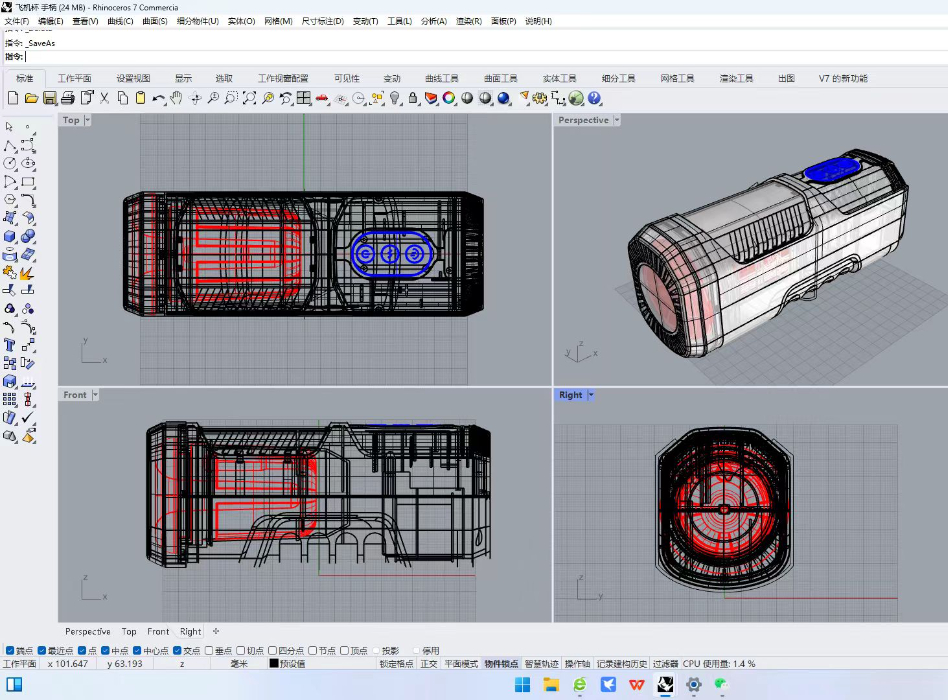

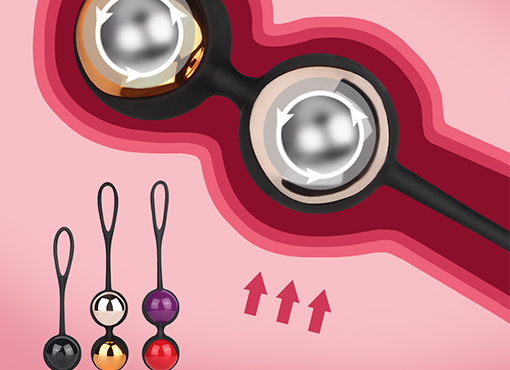

We focused on customize OEM/ODM sexy toy, specialized in research & development, design, manufacturing and sales.

We are committed to providing consumers with safe, comfortable, and pleasurable intimate lifestyle solutions.

Our mission is to 'Science empowers pleasure, health leads life,' and promotes the development of the sexy toy industry in the direction of specialization, quality and intelligence.