- About Us +

- Products +

- Innovation +

- Blogs +

- Contact

SERVICE

NDA

NDA

In order to better protect product R & D and Design, prevent imitators from plagiarizing your unique design concepts and innovative technologies.

We can both sign an NDA agreement, depending on your needs, and ensure that new products are protected.

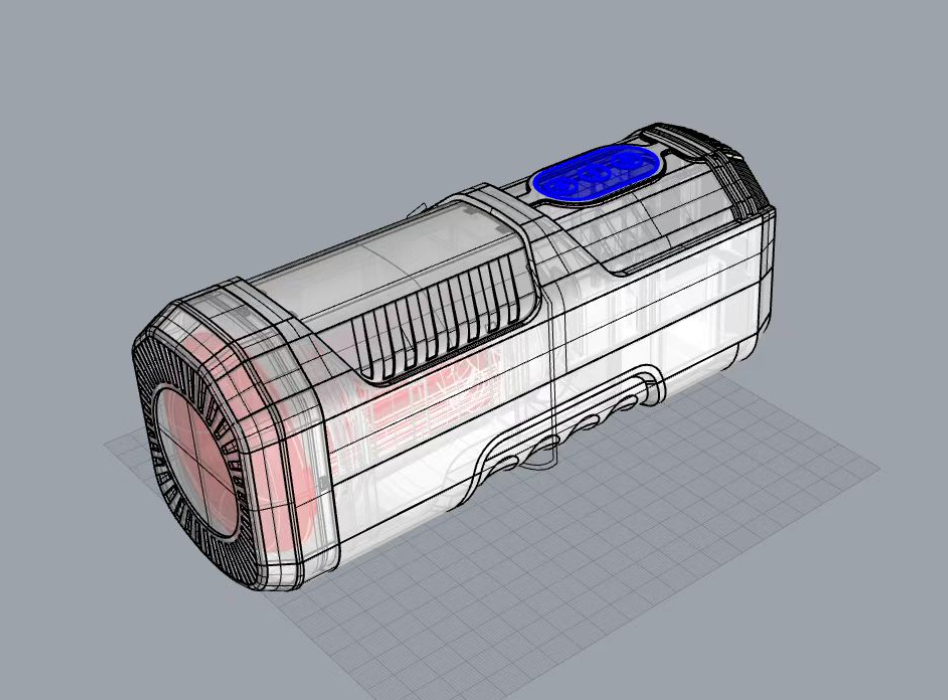

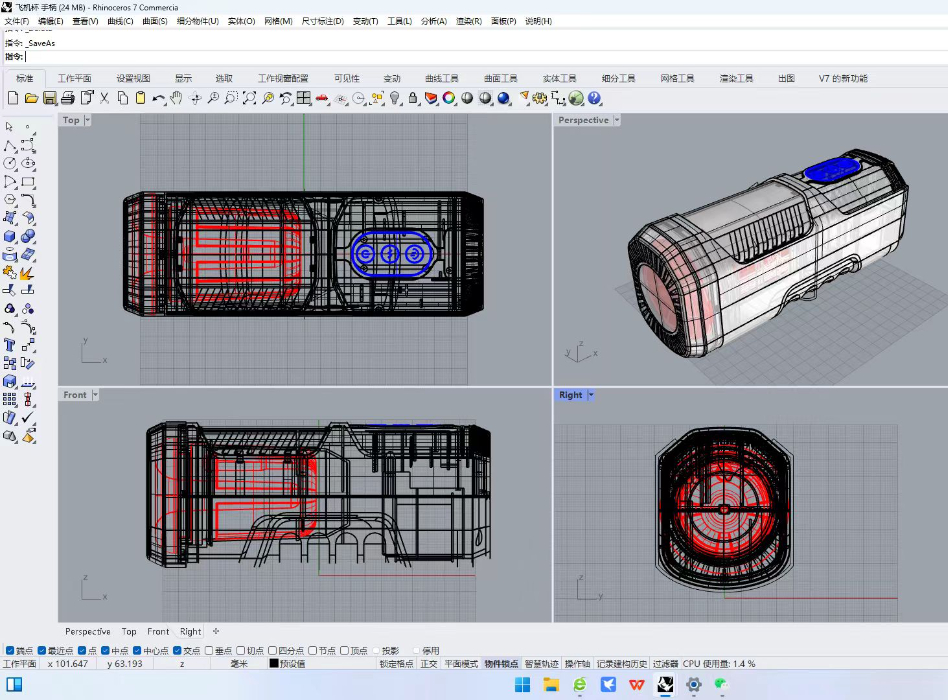

MAKE DRAWING

MAKE DRAWING

Product designers and engineers will use CAD to draw 2D and 3D versions of the product, based on the customer's ideas, ensuring that the structure of the product is ergonomic.

The appearance of the entire product can be rendered through CAD, ensuring that the product design is stylish and artistic.

ENGINEERING

ENGINEERING

In the product structure design, engineers will optimize the design of the internal structure of the product and accurately match the corresponding components.

In electronic design, engineers will design PCB circuit boards, where components and functions are perfect combination.

Engineers will optimize the entire product internal structure and electronic design to achieve optimum product design and performance.

PROTOTYPING

PROTOTYPING

Usually 3D printing or simple molding is used to make the prototype, which can reduce the cost and time to verify whether the internal structure and performance of the product meet the manufacturability.

MANUFACTURING

MANUFACTURING

Our long-term suppliers of raw materials consistently meet our quality and delivery expectations.

We specialize in a full range of services from product research & development, mold manufacturing, plastic injection molding, silicone molding, CNC & EDM machining, electronic assembly and 3D printing to finished product assembly.

Now has 2000 square meters of production workshop, including mold workshop, injection molding workshop, silicone workshop, assembly workshop, warehouse, etc.

There are 120 employees, including 6 members of the technical research and development team and 15 members of the management team. 60 sets of various production and testing equipment, three 15-meter dust-free assembly lines, and all production processes are completed independently.

QUALITY INSPECTION

QUALITY INSPECTION

LIT will conduct a series of rigorous tests and inspections for each product, including but not limited to:

*Waterproof test *Salt spray test

*Noise test *Drop test

*Burn-in test *High and low temperature test

The ultra-low scrap rate of 2% is due to the accurate investigation of subtle potential defects by the quality inspection team with rich experience to ensure product reliability and durability.

COMPLIANCE

COMPLIANCE

Our products undergo rigorous quality control and testing to ensure compliance with safety standards and certification requirements in Europe, America, and beyond.

And comply with relevant regulations and directives in the European and American markets, such as CE, UKCA certification, REACH, Hazardous Substances Restriction Directive, MSDS, FDA testing, etc.

This provides reliable quality assurance for our products, allowing customers to choose and use our products with confidence.

OEM/ODM Solution

OEM/ODM Solution

Solution

CUSTOM PRODUCT TIME AND PROCESS